Damping and protecting in nearly limitless diversity STAB-O-SHOC hydraulic dampers

STAB-O-SHOC protects against the effects of uncontrolled motion during opening, closing, lifting, and lowering. On top of that, this line protects against hazardous vibrations that present a risk to people and machines.

STAB-O-SHOC - Motion and stop dampers

Uncontrolled motion sequences when opening and closing or lifting and lowering flaps are dangerous, not very comfortable and stress the material. Stabilus motion and stop dampers of the STAB-O-SHOC series solve this problem.

They support the controlled motion sequence and protect the material by avoiding a hard impact in the end position.

Functionality

STAB-O-SHOC HD dampers from Stabilus are the most cost-effective variant for safely and reliably damping uncontrolled motion sequences.

As standard motion and flap dampers, they are characterized by their simple design - combined with low manufacturing costs. Further advantages are their high quality and safety standard, extraordinary performance and long service life.

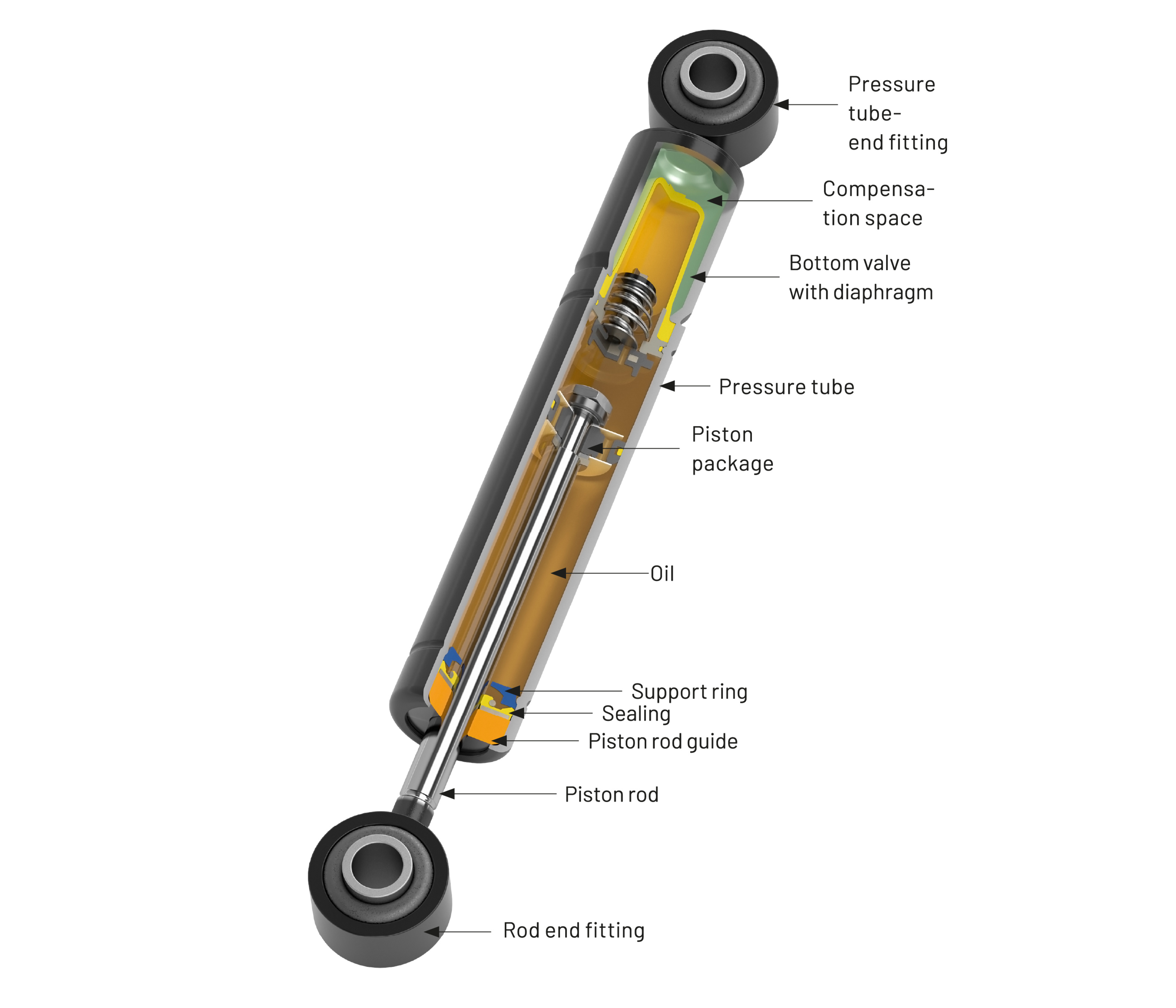

STAB-O-SHOC oil-hydraulic motion or flap dampers differ in the design of the damping force in the direction of tension or compression. Characterizing this is the required damping force in only one direction of movement. By means of bypass grooves, the damping can additionally be varied over the stroke in a path-dependent manner.

As simple damper and motion dampers, they are designed for a position-dependent, vertical installation position. However, equipped with an additional, closed separating element, they can also be installed without any problems in a position-independent manner. This also makes them ideal for use as vibration dampers.

.Motion stop damper with low damping force

|

With idle stroke |

With extension force |

Product |

Short description |

|---|---|---|---|

|

X |

STAB-O-SHOC HD 15 |

Position-dependent standard damper for low damping forces |

|

|

X |

X |

STAB-O-SHOC GD 15 |

Location-dependent standard damper for low damping forces with additional extension force |

|

X |

STAB-O-SHOC GD 15 SP |

Damper for low damping forces with idle stroke-free force transmission in both directions of movement, any mounting position and additional extension force |

Motion stop damper for high load

|

With idle stroke |

With extension force |

Product |

Short description |

|---|---|---|---|

|

X |

STAB-O-SHOC HD 24/29 |

Position-dependent standard damper for high damping forces |

|

|

X |

X |

STAB-O-SHOC GD 24/29 |

Position-dependent damper with separating piston for high damping forces in tension and compression, but with additional extension force |

|

X |

STAB-O-SHOC GD 24/29 SP |

Damper with separating piston, for higher damping forces with idle stroke-free force transmission in both directions of movement, additional extension force and any mounting position |

STAB-O-SHOC - Vibration damper

Unwanted vibrations disturb the smooth running of machines and devices and thus shorten their service life.

Vibration dampers from Stabilus convert the kinetic energy of moving components into thermal energy. In this way, they help to mitigate hard stops and avoid large vibration amplitudes.

Functionality

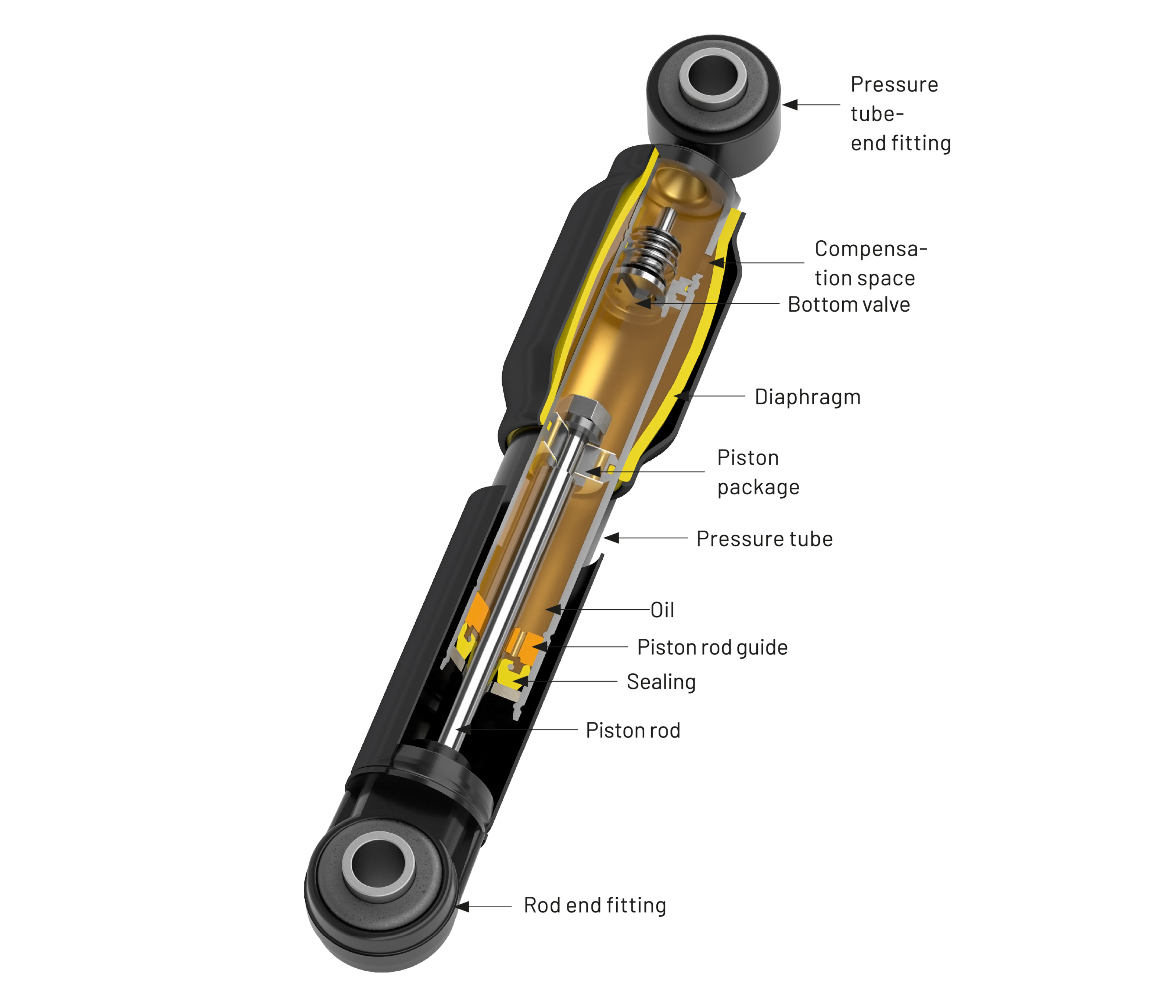

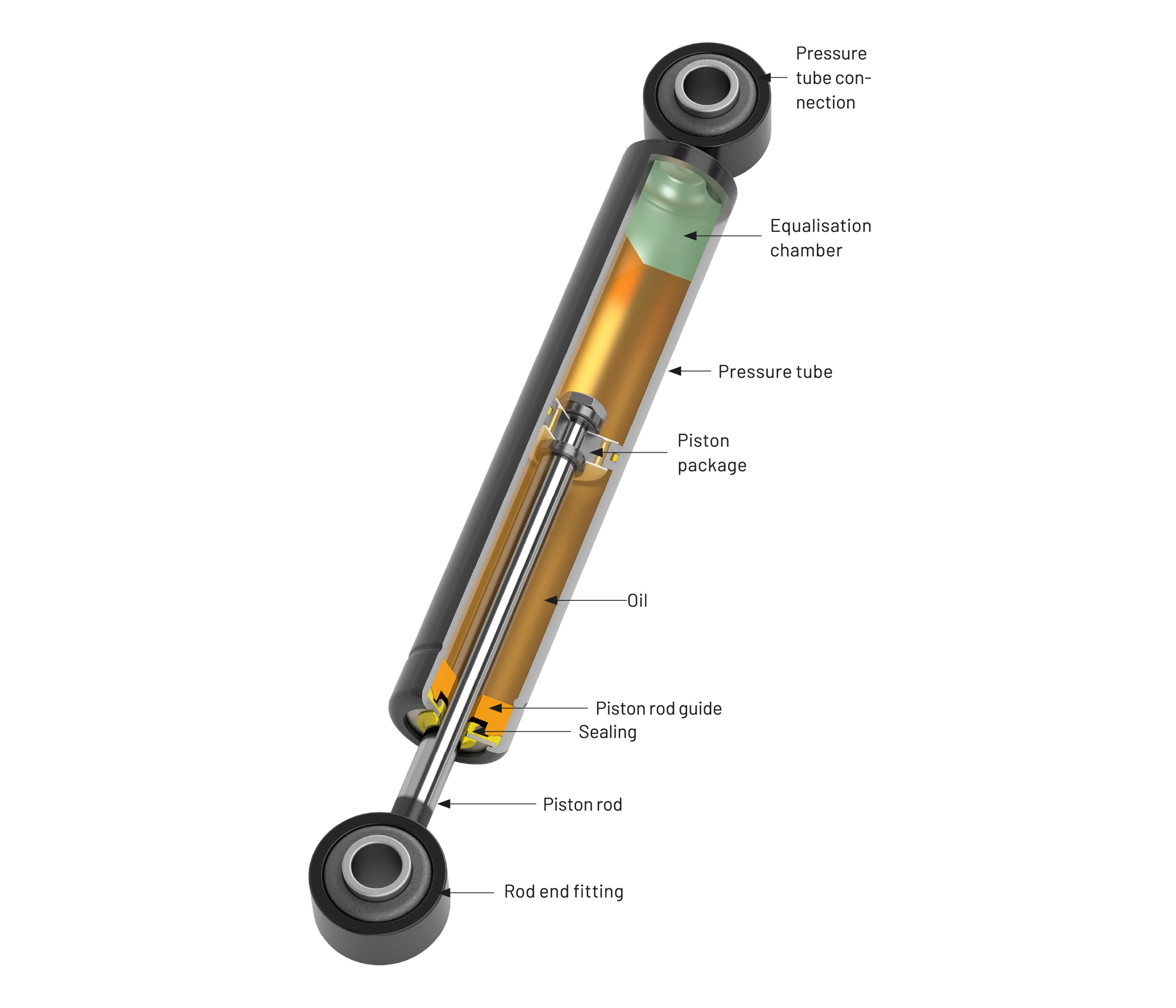

Oil-hydraulic vibration dampers of the STAB-O-SHOC series generally feature symmetrical force distribution in the direction of tension and compression.

Typical designs of the vibration dampers guarantee uniformly defined damping even when motion is reversed.

When the load is reversed, the damping force starts immediately, i.e. the vibration dampers are directly force-locked, and the force transmission is free of idle stroke. With specially integrated piston systems, the forces in the direction of tension and compression can be adjusted individually and independently of one another.

Different design elements change their regulating effect on vibrations. Depending on the design, they also enable position-independent installation.

Selection matrix STAB-O-SHOC - vibration damper

|

Product |

Short description. |

|---|---|

|

STAB-O-SHOC GD 15SP |

Vibration damper with separating piston for horizontal vibration load and light damping force. |

|

STAB-O-SHOC HD 24/29 BV |

Vibration damper for high damping forces and vertical mounting position |

|

STAB-O-SHOC HD 24/29MB |

XStandard vibration damper with bottom valve and diaphragm for high damping forces and any mounting position |

|

STAB-O-SHOC TA damper |

Vibration damper for compact designs and any mounting position |