Learn how to do it Tips and info regarding the proper handling of gas springs

The technical design of a gas spring must be aligned with its specific application – everything is based on drawings and specifications. But if you’re looking for replacement parts and something about the technical specifications is unclear, just get in touch with us.

We have also put together some handy tips and tricks for the correct installation and handling of gas springs. These instructions are essentially universal and should make your job a little easier.

Application

In their technical design, gas springs must be customized for special applications – on the basis of specifications and drawings. Match your application and requirements with us. Our consultants will be glad to help you.

Mounting Orientation

If possible, install gas springs so that the piston rod points down in the inactive state – unless they were designed for non-orientation specific installation. This will ensure optimum lubrication of the guide and sealing system at all times.

No Jamming

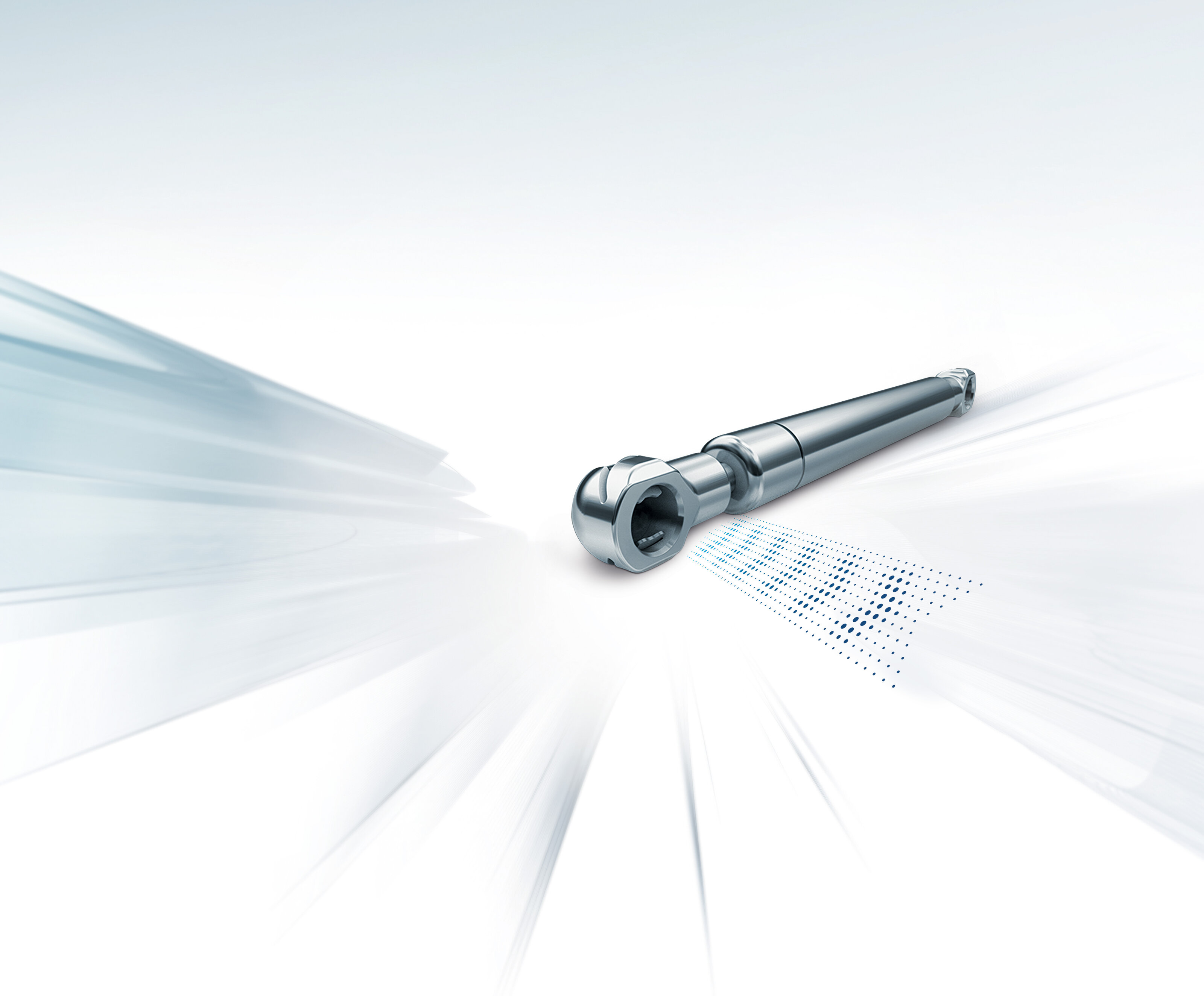

For a long service life, gas springs must not jam or be subjected to bending or lateral forces. We offer suitable end fittings, such as angle joints. They will ensure non-jamming alignment.

Functional Safety

The functional safety of a gas spring comes mainly from the smooth piston rod surface and the seals that keep the gas pressure on the inside. Do not subject gas springs to bending stresses. You should not install gas springs that have been damaged in after-sales mechanical processing. Welding on the gas spring, as well as contamination or paint on the piston rod can cause device failure. Avoid modifications and manipulations, impacts, tensile stress, heating, painting, and removal of the imprint. Be on the safe side: Do not install defective or improperly altered products.

Temperature Range

Stabilus gas springs are designed for a default temperature range of -30°C to +80°C. Of course, there are also gas springs for more extreme applications.

Life and Maintenance

Gas springs are maintenance-free! They do not require greasing or lubrication. They are designed for their corresponding applications and will work flawlessly for many years.

Transportation and Storage

Store gas springs with the piston rod pointing down. Actuate the gas spring after 6 months of storage. Avoid damage: Do not transport gas springs as bulk material. Make sure not to contaminate gas springs with thin packaging film or adhesive tape.

Disposal

When gas springs are no longer needed, they should be disposed of in an environmentally correct manner. For this purpose they should be drilled open, the compressed nitrogen gas bled, and the oil drained. For more specific details, please refer to STAB specification 1000 9375.

Mounting

Proper alignment

Functional safety

The functional safety of a gas spring is primarily ensured by the smooth piston rod surface as well as the seals, which maintain the pressure of the gas in the spring’s interior. Therefore, it is unsafe to subject a gas spring to bending forces. Never install gas springs that have been damaged by subsequent mechanical processing. Welds on the gas spring as well as contamination or paint on the piston rod can lead to equipment failure. Do not allow alterations, distortion, impacts, tensile stress, heating, application of coatings, or removal of printed or embossed information. Always be on the safe side: Do not install products that are defective or damaged.

Temperature range

Service life and maintenance

Transport and storage

Do not ship gas springs as bulk cargo, as this may result in damage. Ensure that gas springs will not become contaminated as a result of adhesives or thin packaging film. If possible, do not expose our gas springs to contamination. That’s also why we recommend storing them in a sealed outer package.

Disposal

Once a gas spring is no longer needed, it should be disposed of in an environmentally friendly manner. It should be properly drilled out as part of this process in order to release compressed nitrogen gas and the oil contained in the spring. Please refer to STAB Spec. 1000 9375 for more information.